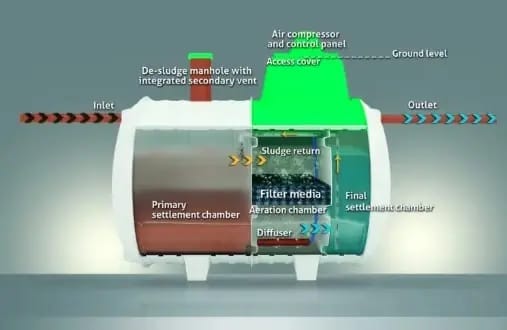

The Tricel Novo is designed for domestic and light commercial applications, the submerged aeration sewage treatment plant utilises a proven fixed bed technology for its own treatment system.

The plant consists of three independent treatment zones, each serving different stages of the sewage purification process.

These highly efficient sewage treatment plants can accommodate populations ranging from 1 to 50 PE (Population Equivalent).

Tricel Novo products are manufactured from the robust glass-reinforced polymer material ? SMC, ensuring a resilient and durable solution.

SEWAGE TREATMENT PLANT KEY BENEFITS:

Compression moulded SMC tank: Employing one of the most advanced technological processes, compression moulding is utilised for crafting structural composites. Components undergo manufacturing under high heat and pressure, exhibiting unparalleled strength and durability compared to standard GRP or PE tanks.

SMC stands out in the sewage treatment industry, with Tricel SMC tanks operating in some of the most challenging climatic conditions without defects.

Tricel?s ceramic diffuser, a distinctive feature in the domestic sewage treatment plants market, boasts twice the lifespan of standard rubber equivalents, leading to cost savings in call-out fees and replacement parts.

Installation on most sites requires no concrete backfill.

The plant operates with no moving parts or pumps, ensuring reliable operation and minimizing maintenance and repair costs.

Tricel Novo plants are designed with a shallow invert, reducing both installation costs and time.

Factory-fitted alarm *Excludes Novo SR

Integrated pumped outlet *Excludes Novo SR

Approved to the European Standard EN12566-3, these systems have earned the CE Mark after thorough testing in an independent laboratory for nine months.

20-year warranty is provided for the SMC structure.

3-year warranty covers mechanical parts *Excludes Novo SR